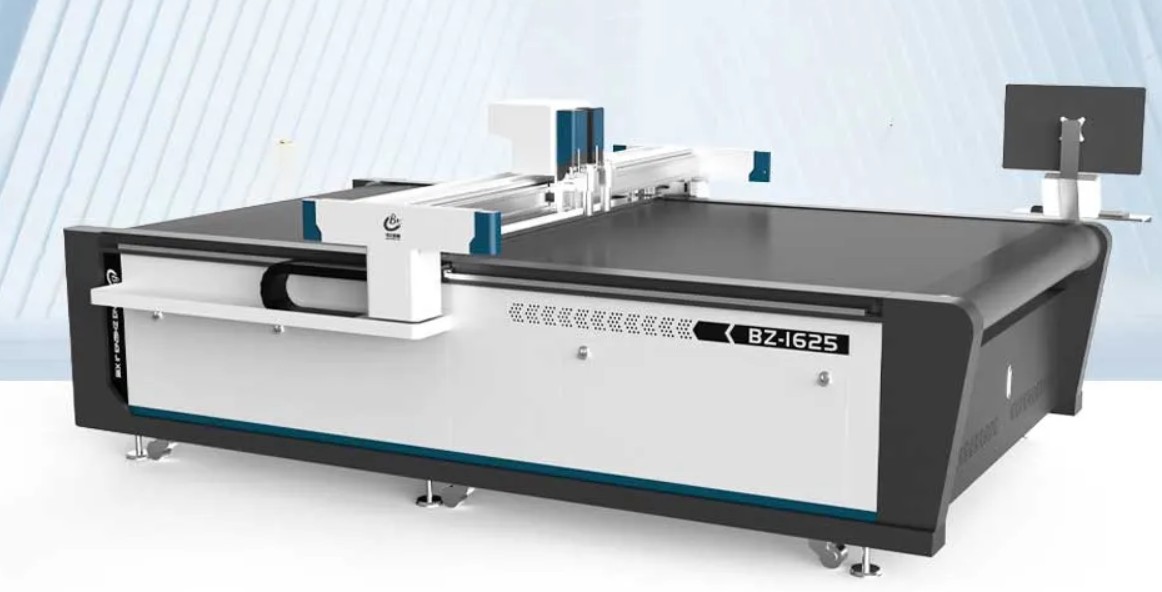

Choosing the right CNC automatic fabric cutter is crucial for businesses that deal with textiles and flexible materials. A good cutting machine manufacturer can provide machines that improve efficiency, reduce waste, and offer precise cuts. DIGITAL CUTTING MACHINE SUPPLIERS stands out in this space, providing reliable machines with ISO 9001 certification. They focus on delivering both quality and support, ensuring customers get machines that meet industrial standards. Whether you’re making garments, upholstery, or technical textiles, these machines can handle complex patterns accurately. DIGITAL CUTTING MACHINE SUPPLIERS has over 200 employees and serves more than 3,000 customers worldwide, making them a trusted choice. Learn more about their products at CompanyWebsite.com.

What is a CNC Automatic Fabric Cutter?

A CNC automatic fabric cutter is a machine designed to cut fabrics automatically using computer numerical control. The system follows digital patterns to make precise cuts, eliminating manual errors. Unlike traditional cutting methods, CNC machines can handle multiple layers of fabric simultaneously, saving time and labor. These machines often include features like automatic feeding, high-speed cutting, and compatibility with various materials such as cotton, polyester, leather, and technical fabrics.

For example, in a sportswear factory, a CNC cutter can cut 16 layers of fabric in one pass while maintaining accuracy, even under high temperature and humidity. This ensures consistency in production and minimizes material waste.

Benefits of Using CNC Fabric Cutters

Using a CNC automatic fabric cutter brings several advantages for manufacturers.

1. Precision and Accuracy

These machines cut fabrics with minimal deviation, often as precise as ±0.01mm. This ensures uniformity in large production batches.

2. Material Savings

Advanced nesting software allows cutting more pieces from the same fabric roll. Customers report saving up to 12% more fabric compared to manual cutting.

3. Time Efficiency

Automatic feeding and high-speed cutting reduce production time. Some users have halved training times for operators due to simple, intuitive interfaces.

4. Versatility

CNC fabric cutters can handle multiple layers and various materials. From cotton to leather and even composite materials, these machines adapt easily to different projects.

5. Lower Labor Costs

Automation reduces the need for manual labor. Operators mainly monitor the machine, allowing workers to focus on other tasks.

6. Durability and Support

Machines from trusted manufacturers like DIGITAL CUTTING MACHINE SUPPLIERS come with warranty support, lifetime software upgrades, and local technical maintenance.

Features to Look For

When selecting a CNC automatic fabric cutter, consider these key features:

Layer Cutting Capability

A good machine can cut multiple fabric layers at once, improving efficiency in high-volume production.

Cutting Accuracy

Check for machines that maintain consistent precision across different materials and thicknesses.

Software Integration

Machines with user-friendly software help with pattern layout, fabric utilization, and easy file importing.

Maintenance and Support

A reliable manufacturer provides local technical service, training, and timely updates to software and hardware.

Energy Efficiency

Look for machines that minimize energy consumption while maintaining cutting speed and accuracy.

Pros and Cons of CNC Automatic Fabric Cutters

Pros

CNC cutters are precise, fast, and versatile. They save material, reduce labor costs, and can handle complex patterns with multiple layers.

Cons

The initial investment is higher than manual cutting. Some machines require trained operators for optimal use. Maintenance costs can add up if the machine is not regularly serviced.

How to Choose a Cutting Machine Manufacturer

Choosing the right manufacturer is as important as selecting the machine itself. A trusted cutting machine manufacturer ensures quality, service, and long-term support.

Experience and Reputation

Look for companies with years of experience and a proven track record. DIGITAL CUTTING MACHINE SUPPLIERS has been manufacturing CNC cutting machines since 2007, serving over 3,000 clients globally.

Certifications

ISO 9001 certification ensures the machines meet quality standards.

After-Sales Support

Ensure the manufacturer provides local service, technical guidance, and software updates. DIGITAL CUTTING MACHINE SUPPLIERS offers lifetime system upgrades and local maintenance support.

Range of Machines

Manufacturers offering a variety of machines, such as CNC leather cutters, multi-layer cutters, and oscillating knife cutters, provide flexibility as your business grows.

Customer Testimonials

Customer reviews can show real-world performance. One client reported a return on investment in just 11 weeks after switching to an automatic fabric cutter.

Real-World Applications

CNC automatic fabric cutters are used in multiple industries.

Garment Manufacturing

CNC cutters are widely used for producing garments. They ensure identical cuts for shirts, pants, and jackets.

Upholstery

Furniture manufacturers use CNC cutters to cut fabric for sofas and cushions accurately.

Technical Textiles

For materials used in automotive interiors, aerospace, or medical textiles, CNC cutters handle complex shapes and thick fabrics efficiently.

Footwear

Shoes often require multiple layers of material. CNC cutters can handle up to 16 layers simultaneously without compromising precision.

Composite Materials

Beyond textiles, CNC cutters are used to cut PVC, cardboard, felt, and carbon fiber sheets. This versatility makes them suitable for various manufacturing needs.

Tips for Maintaining Your CNC Fabric Cutter

Regular maintenance extends the life of your CNC machine. Keep these tips in mind:

Check blades regularly for wear and replace them as needed.

Clean the machine to prevent fabric dust from affecting sensors.

Ensure software updates are installed promptly.

Train operators to handle minor troubleshooting.

Schedule professional service visits periodically.

These practices keep machines running efficiently and prevent costly downtime.

Verdict: Is It Worth Investing in a CNC Automatic Fabric Cutter?

Investing in a CNC automatic fabric cutter is ideal for businesses aiming to increase productivity, reduce waste, and maintain consistent quality. While the upfront cost is higher than manual cutting, the savings in material, labor, and production time often justify the investment.

Choosing a reliable cutting machine manufacturer is key. DIGITAL CUTTING MACHINE SUPPLIERS offers quality machines, excellent support, and proven results. Their CNC fabric cutters are designed for real industrial conditions and come with a three-year equipment warranty and lifetime system upgrades.

For businesses serious about scaling production and improving efficiency, a CNC automatic fabric cutter is a practical and valuable investment. Learn more about their products at CompanyWebsite.com.

Highlights:

CNC automatic fabric cutters provide precision, speed, and efficiency. Selecting a reputable manufacturer like DIGITAL CUTTING MACHINE SUPPLIERS ensures reliability and support. These machines save material, reduce labor costs, and handle complex projects with ease, making them a smart choice for modern textile manufacturing.