Managing facilities across different sectors taught me that motor controls vary significantly by application. Industrial motor controls handle heavy machinery and continuous operation demands. They’re built differently than lighter-duty options. Commercial motor controls serve building systems like HVAC and elevators with different priorities. I learned these distinctions through six years of hands-on experience. This review shares what works, what doesn’t, and why the differences matter.

Electrical Distribution & Control is a family-owned supplier serving both local and nationwide customers. They specialize in hard-to-find electrical distribution and motor control products. The company provides recycled, reconditioned, and new equipment for various industrial and commercial applications.

How I Discovered These Differences Matter

My career started in commercial property management. Office buildings and retail centers. Then I moved to industrial facility management. Manufacturing plants and warehouses. The transition shocked me.

I thought motor controls were universal. Same principles, same parts, just different sizes. That assumption cost me dearly. A motor starter from my commercial supplier failed within days in the plant.

The failure shut down a production line. Cost the company $15,000 in lost output. My boss wasn’t happy. The maintenance crew wasn’t happy. I felt terrible about the mistake.

An experienced electrician explained the problem. Commercial-grade controls can’t handle industrial duty cycles. The heat. The vibration. The continuous operation. Different worlds entirely.

That expensive lesson taught me to understand applications first. Then match components appropriately. Never assume parts are interchangeable. Context determines requirements completely.

Understanding Industrial Application Demands

Manufacturing equipment runs continuously. Eight-hour shifts minimum. Often 12 or 24 hours. Some operations never stop. Motors and controls must handle sustained loads.

Duty cycles in industrial settings stress components. Starting and stopping heavy machinery. Frequent reversing on some equipment. High inrush currents during startup. Controls must survive these conditions.

Environmental factors are harsh. Heat from processes. Vibration from machinery. Dust and contamination. Sometimes moisture or chemicals. Protection ratings matter enormously.

Motor sizes tend larger in industrial settings. 50 HP and up is common. Some applications use hundreds of horsepower. Control components must match these power levels. Oversizing for safety margins is standard practice.

Three-phase power is universal in industry. Usually 480V. Sometimes higher voltages. Control voltage often differs from motor voltage. Transformers and additional components are necessary. System complexity increases accordingly.

Reliability requirements are extreme. Downtime costs thousands per hour. Sometimes more. Equipment must work when needed. Preventive maintenance is scheduled. But unplanned failures are catastrophic.

Safety interlocks are mandatory. Emergency stops must function perfectly. Overload protection prevents motor damage. These aren’t optional features. They’re required by regulations and insurance.

Commercial Applications Work Differently

Building systems operate intermittently. HVAC cycles on and off. Elevators start and stop frequently. Exhaust fans run when needed. Different duty cycle than continuous industrial operation.

Motor sizes are generally smaller. 5-20 HP for most applications. Larger motors for chillers and cooling towers. But nothing like industrial machinery. Controls can be lighter duty accordingly.

Environmental conditions are controlled. Indoor installation usually. Temperature regulated. Dust minimal. Moisture rare except specific applications. Standard enclosure ratings suffice usually.

Load patterns are predictable. HVAC responds to thermostats. Elevators follow call patterns. Exhaust fans react to sensors. This predictability simplifies control requirements. Less need for heavy-duty components.

Single-phase and three-phase both exist. Voltage typically 208V or 240V. Lower than industrial standards. Control voltages often match motor voltages. Simpler electrical design in many cases.

Maintenance windows are tighter. Can’t shut down during business hours. Work happens evenings and weekends. This scheduling constraint affects how you approach repairs. Quick fixes become necessary sometimes.

Life safety systems have specific requirements. Elevator controls are heavily regulated. Fire alarm integration is mandatory. Emergency lighting must function. These requirements differ from industrial needs.

My First Major Industrial Motor Control Challenge

A packaging line motor controller failed at a manufacturing plant. Production stopped immediately. We needed replacement urgently. Every hour of downtime cost $3,000.

I called my usual commercial suppliers first. They had motor starters in stock. Specifications seemed to match. Amperage, voltage, horsepower ratings all correct. I ordered one for rush delivery.

The electrician installed it that afternoon. Seemed to work initially. Motor started fine. Line ran for two hours. Then the new control failed catastrophically. Contacts welded together. Motor kept running after shutdown command.

Emergency stop prevented damage. But we were back to square one. Now I’d wasted four hours and $800. The plant manager was beyond frustrated. Pressure mounted significantly.

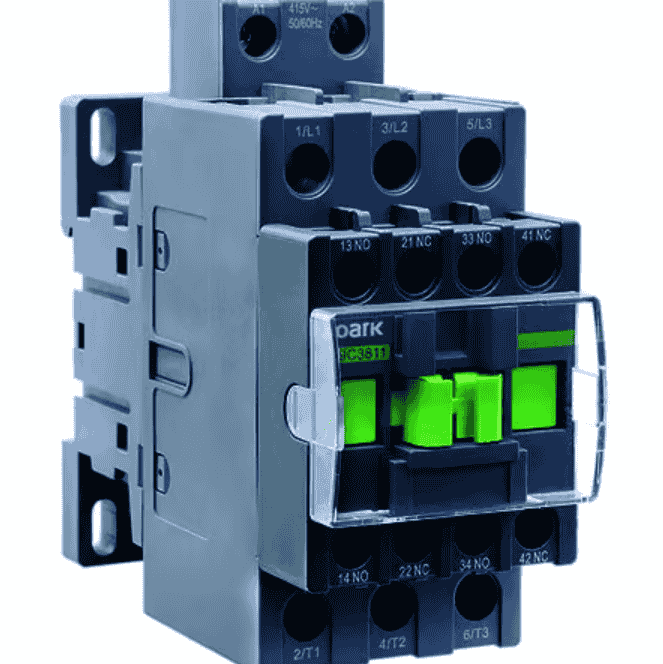

I called Electrical Distribution & Control. They asked detailed questions about the application. Duty cycle. Starting frequency. Ambient temperature. Environmental conditions. This questioning revealed my mistake.

They explained that commercial-grade controls won’t survive industrial applications. Different contact materials. Different arc suppression. Different thermal design. My parts were inadequate regardless of matching specs.

They had proper industrial motor controls in stock. AC rated for the duty cycle. Designed for continuous operation. Properly sized for the application. Delivered same day locally.

That control worked perfectly. Still running three years later. The extra cost was $200 more than commercial grade. But it actually worked. Cheap parts aren’t cheap when they fail repeatedly.

Comparing Construction and Durability

Industrial controls use heavier contact materials. Silver-cadmium or silver-tungsten alloys. These withstand arc damage better. Last longer under heavy use. Essential for industrial duty cycles.

Commercial controls use lighter materials. Adequate for intermittent operation. Cost less to manufacture. Work fine in proper applications. But fail quickly under industrial stress.

Coil construction differs significantly. Industrial coils handle temperature extremes. Better insulation materials. More robust wire. Designed for harsh environments. Commercial coils are lighter duty.

Enclosure ratings protect against environment. Industrial controls often need NEMA 12 or higher. Protection from dust, moisture, corrosion. Commercial applications use NEMA 1 frequently. Indoor, controlled environments.

Arc suppression is critical in industrial controls. Larger air gaps between contacts. Better arc chutes. Magnetic blowouts on some models. These features handle high fault currents safely. Commercial controls lack these protections.

Mechanical life ratings differ dramatically. Industrial controls rated for millions of operations. Commercial controls rated for hundreds of thousands. This difference reflects expected duty cycles. Choose based on actual usage patterns.

Real-World Cost Comparisons

Commercial motor controls cost less initially. A 10 HP motor starter runs $150-300. Depends on brand and features. Readily available from standard suppliers. Lead times are short.

Industrial motor controls cost significantly more. Same 10 HP capacity costs $400-600. Premium for heavy-duty construction. Better materials and design. Worth it for the application.

But cheap controls that fail create hidden costs. Downtime in industrial settings is expensive. Emergency service rates are high. Replacement labor costs add up. Total cost of cheap parts exceeds quality parts.

I learned this lesson expensively. Buying wrong controls cost $4,000 total. The correct control cost $600. My penny-pinching created $3,400 in unnecessary expense. False economy at its worst.

Reconditioned industrial controls offer value. Properly tested units from reputable suppliers. Often half the cost of new. Still rated for industrial duty. Smart option for budget-conscious operations.

Commercial reconditioned parts are available too. Less savings compared to new. But still worthwhile for replacement applications. Quality reconditioning ensures reliability. Guarantees provide protection.

Emergency Situations Reveal True Capabilities

A chiller motor control failed at midnight. Office building in summer. Temperature rising fast. Tenants would be miserable by morning. Emergency situation clearly.

Commercial controls for HVAC are common. Several suppliers had parts. But none answered after hours. Their emergency numbers went to voicemail. No actual human help available.

One supplier did answer. Electrical Distribution & Control’s emergency line. They checked inventory immediately. Had compatible control in stock. Offered to meet me at their shop.

By 2 AM, I had the part. By 4 AM, we had cooling restored. Building comfortable by business hours. Crisis averted through good supplier relationship. That responsiveness is invaluable.

An industrial facility lost a motor starter. Critical conveyor system. Production stopped completely. Every hour cost $5,000 in lost output. Pressure was intense.

Standard suppliers couldn’t help. Part was obsolete. Manufacturer discontinued that line. Suggested complete system replacement. That would take weeks and cost $50,000.

Specialists in obsolete parts located a reconditioned unit. Tested and guaranteed to work. Shipped overnight. Installed next morning. Production resumed 18 hours after failure. Total cost under $2,000.

These experiences show why supplier relationships matter. Having sources for different needs. Emergency capabilities. Obsolete parts expertise. These services prevent disasters.

Understanding Control Ratings and Selection

Horsepower ratings seem straightforward. But voltage matters too. A 10 HP control at 480V differs from 10 HP at 240V. Current ratings change significantly. Always match voltage and horsepower together.

AC versus DC ratings aren’t interchangeable. AC controls use arc suppression designed for alternating current. DC creates sustained arcs. Needs different contact materials and arc chutes. Using wrong type is dangerous.

Duty cycle ratings indicate expected usage. Continuous duty means 24/7 operation. Intermittent duty assumes rest periods. Industrial applications usually need continuous ratings. Commercial often uses intermittent.

Ambient temperature affects ratings. Controls derated for high temperatures. Industrial locations often exceed standard 40°C ambient. Need appropriate derating or cooling. Commercial spaces stay temperature controlled usually.

Enclosure ratings protect electronics. Indoor dry locations use basic enclosures. Outdoor or wet locations need weatherproof ratings. Hazardous locations require explosion-proof. Match enclosure to environment.

Overload protection prevents motor damage. Thermal overloads sense temperature. Magnetic overloads sense current. Industrial applications often use both. Commercial typically uses thermal only. Protection level matches application risk.

Maintenance Approaches Differ by Application

Industrial facilities schedule preventive maintenance. Regular inspections catch problems early. Contacts cleaned. Connections tightened. Worn parts replaced before failure. This prevents unplanned downtime.

I implemented quarterly inspections at industrial sites. Found issues before they caused shutdowns. Replaced 15-20 components annually preventively. Reduced emergency failures by 70%. Proactive maintenance pays off.

Commercial buildings often do reactive maintenance. Fix things when they break. Less frequent inspections. This approach works because failure costs are lower. Downtime affects comfort, not production.

Documentation matters in both settings. Record installations and replacements. Track failure patterns. Note solutions that worked. This information guides future decisions. Institutional knowledge prevents repeating mistakes.

Training matters more in industrial settings. Multiple operators need troubleshooting skills. Emergency stops must be understood. Safety procedures are critical. Commercial buildings rely on contractors usually.

Spare parts inventory makes sense industrially. Critical components stocked on-site. Prevents waiting for deliveries. Expensive but justified by downtime costs. Commercial buildings rarely maintain parts inventory.

What Makes Motor Control Suppliers Reliable

Technical knowledge separates good suppliers from great ones. Staff should understand applications. Not just read specs. Real troubleshooting experience helps customers. This expertise prevents costly mistakes.

Inventory depth matters for emergencies. Having parts in stock prevents delays. Deep inventory serves diverse needs. This capability is essential during crises. Standard suppliers can’t compete here.

After-hours availability helps industrial operations. Equipment fails anytime. Having emergency access prevents extended downtime. This service level differentiates premium suppliers. Worth paying more for availability.

Testing procedures for reconditioned parts are essential. Good suppliers test under load. Verify all functions. Replace worn components. Document the process. Poor suppliers do minimal testing.

Honest communication about capabilities builds trust. Admitting when they can’t help. Not guessing about compatibility. Clear about lead times. Transparent pricing. These qualities prevent problems.

Obsolete parts expertise fills important gaps. Many industrial operations use old equipment. Finding discontinued parts enables continued operation. This specialization serves real needs. Companies like Electrical Distribution & Control focus on this market.

Lessons from Six Years Managing Both

Match components to actual duty cycles. Don’t undersize for cost savings. Failures cost more than proper parts. This applies to both industrial and commercial. But consequences differ.

Build relationships with multiple suppliers. No single source has everything. Industrial specialist. Commercial supplier. Obsolete parts expert. Different sources for different needs. Maintain these relationships actively.

Document everything about your systems. Equipment installed. Parts used. Suppliers contacted. Solutions that worked. This information saves time later. Prevents repeating research unnecessarily.

Plan for obsolescence before it happens. Equipment ages. Parts discontinue. Start sourcing alternatives early. Don’t wait for emergency. Proactive approach reduces stress.

Quality beats price in critical applications. Industrial downtime costs justify premium parts. Commercial applications allow more flexibility. But reliability always matters. Choose appropriately for situation.

Emergency service capability is worth premium pricing. When equipment fails, fast response prevents losses. Having suppliers who actually help matters. Test emergency numbers before crises.

Final Thoughts and Recommendations

Industrial motor controls and commercial motor controls serve different purposes. Construction differs. Ratings vary. Costs reflect capabilities. Understanding these differences prevents expensive mistakes.

My early career mistake taught valuable lessons. Match parts to applications carefully. Don’t assume interchangeability. Ask questions about duty cycles and environments. Verify compatibility thoroughly.

Finding reliable suppliers makes everything easier. Companies like Electrical Distribution & Control serve important niches. Their focus on hard-to-find parts helps facilities with older equipment. Reconditioning programs offer quality at lower costs.

For facility managers in any sector, build your supplier network thoughtfully. Identify specialists for different needs. Establish accounts before emergencies. Test their capabilities with small orders first.

Visit https://edc-electrical.com/ to explore one example of specialized suppliers. Review their capabilities. Consider their services. Even if you don’t need them today, knowing they exist helps during emergencies.

The industrial and commercial sectors have distinct needs. Equipment differs appropriately. Controls match applications. Suppliers specialize accordingly. Understanding these differences improves sourcing decisions.

Would I recommend taking time to understand these distinctions? Absolutely yes. My expensive mistake proves the value. Proper knowledge prevents failures. Right parts prevent downtime. Good suppliers prevent crises. These lessons apply across all facility types.